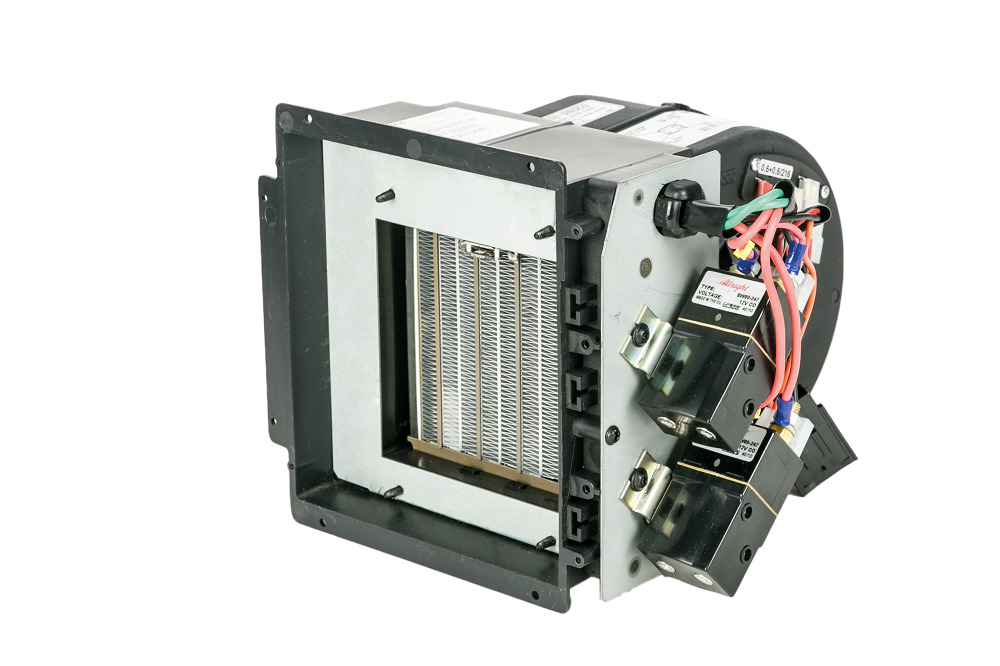

CALENTADOR ELÉCTRICO

Descubra todos nuestros calentadores eléctricos estándar, disponibles en 12 V, 24 V o 48 V, con filtros de aire y termostato de seguridad, equipados con tecnología PTC, probada y validada por SIROCO ENGINEERING France. Se pueden montar distintas fachadas: con difusores de aire, manguitos o rejilla. Para cualquier solicitud específica, póngase en contacto con nosotros.